A smokehouse in food processing is a sophisticated, controlled environment – ranging from traditional, small-scale structures to large, industrial chambers – primarily designed for imparting smoke flavor, color, and aroma to food products, most commonly meats, poultry, and fish. While its historical roots are firmly in food preservation through drying and the antimicrobial properties of smoke, modern smokehouses in commercial settings prioritize sensory attributes and often integrate cooking and chilling stages.

Here's a breakdown of its key aspects:

Primary Functions of a Modern Smokehouse:

Flavor and Aroma Impartation: This is arguably the most significant function today. Smoke contains a complex array of compounds (phenols, carbonyls, organic acids, etc.) that react with food components to create the distinctive, desirable "smoky" taste and smell. The type of wood used (e.g., hickory, mesquite, applewood, cherry) profoundly influences the final flavor profile.

Color Development: Smoking gives food products an attractive golden-brown, reddish, or mahogany hue, which is highly appealing to consumers. This color results from reactions between smoke components and food proteins, as well as the Maillard reaction that occurs during hot smoking.

Texture Modification: The heat and drying effects of smoking contribute to the texture of the finished product. Hot smoking, in particular, cooks the food, firming its texture. Cold smoking, while not cooking, can still slightly dry the surface, developing a "pellicle" which aids in smoke adherence and gives a chewier bite.

Limited Preservation (Secondary): While modern refrigeration and packaging are the primary preservation methods, smoke still offers some antimicrobial and antioxidant properties. Compounds in smoke can inhibit bacterial growth and reduce oxidative spoilage, contributing to a slightly extended shelf life and overall product stability.

Types of Smokehouses:

Smokehouses can be broadly categorized by their operational method:

Batch Smokehouses:

These are essentially chambers where a specific quantity of food is loaded at once.

The food typically hangs on racks or is placed on trays.

The entire smoking process (drying, smoking, cooking, chilling) is carried out within this single chamber for the loaded batch.

They offer flexibility for smaller runs or diverse product types.

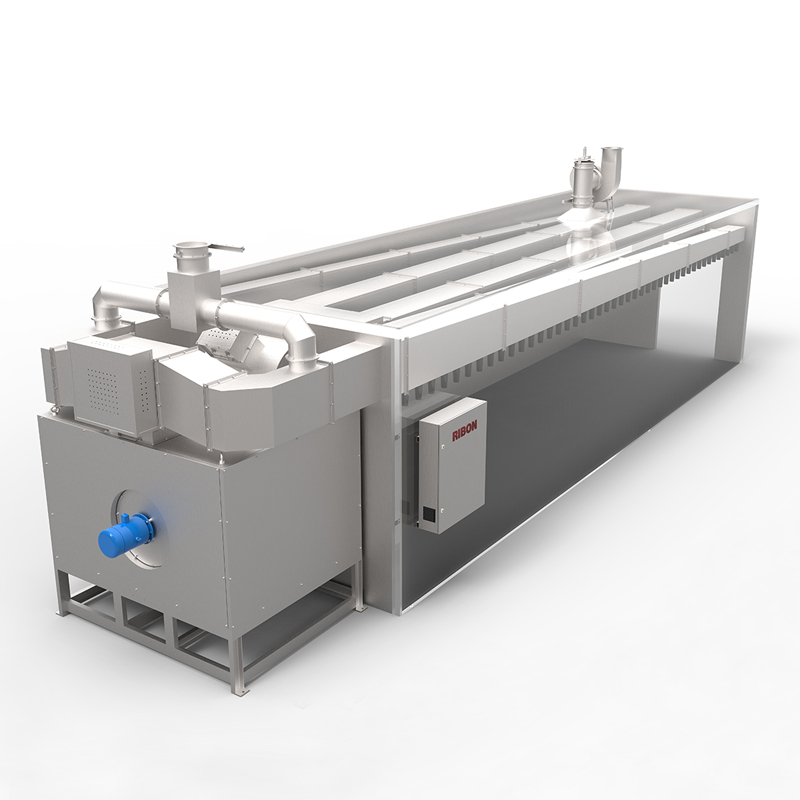

Continuous Smokehouses:

Designed for high-volume production.

Food products (e.g., sausages, ham) are typically hung on "sticks" or trolleys and conveyed continuously through different zones within the smokehouse.

These zones might include:

Drying/Tempering Zone: To prepare the surface for optimal smoke absorption.

Smoking Zone: Where smoke is introduced.

Cooking Zone: For hot smoking, ensuring the product reaches a safe internal temperature.

Chilling Zone: Rapidly cools the product to prevent bacterial growth and maintain quality.

Continuous systems are highly automated and ensure consistent product quality for large-scale operations.

Smoke Generation Methods:

The smoke itself can be generated in several ways:

Natural Smoke Generators (Wood-based):

This is the most traditional and common method.

Hardwood chips or sawdust (e.g., hickory, mesquite, alder, oak, fruit woods) are slowly smoldered or pyrolyzed (heated in the absence of oxygen) in a separate smoke generator unit.

The smoke produced is then ducted into the smokehouse chamber.

This method offers the most authentic and complex flavor profiles.

Liquid Smoke:

Liquid smoke is produced by condensing and purifying natural wood smoke.

It's applied to food by spraying, dipping, drenching, or even injecting it.

While convenient and offering consistent flavor, some argue it lacks the depth and complexity of natural wood smoke. It's often used in conjunction with a light natural smoke for color and some flavor notes.

Friction Smoke Generators:

These generators create smoke by pressing a log or block of wood against a rapidly rotating wheel or disc, causing friction and heating that generates smoke. They offer good control over smoke density.

Key Process Parameters and Control:

Modern industrial smokehouses are highly sophisticated and feature precise controls over various parameters to ensure product consistency, safety, and quality:

Temperature: Critical for both cold smoking (low temperatures, typically below 100°F/38°C, for flavor without cooking) and hot smoking (higher temperatures, typically 120-180°F/50-82°C, to cook the product).

Humidity: Controlled humidity prevents excessive drying or condensation, ensuring optimal smoke adherence and product texture.

Airflow: Proper air circulation ensures uniform smoke distribution and heat transfer throughout the chamber, leading to consistent smoking of all products.

Smoke Density/Concentration: Regulated to achieve the desired intensity of smoke flavor and color.

Processing Time: Varies significantly depending on the product, desired smoke intensity, and whether the product is hot or cold smoked.

Construction and Safety:

Smokehouses are typically constructed from durable, food-grade materials like stainless steel, designed to withstand high temperatures, corrosive smoke, and rigorous cleaning. They often include:

Insulation: To maintain stable internal temperatures and energy efficiency.

Ventilation Systems: To manage smoke exhaust and ensure proper air exchange.

Cleaning Systems: Automated wash-down cycles are common to maintain hygiene.

Safety Features: Fire suppression systems and interlocks are crucial given the presence of heat and combustible smoke.

The smokehouse has evolved from a simple preservation shed into a technologically advanced piece of equipment central to the production of a wide array of flavorful and aesthetically pleasing smoked food products in the modern food industry.

English

English русский

русский Español

Español عربى

عربى