Slaughtering cattle involves a series of carefully controlled steps designed to ensure efficiency, safety, and adherence to humane practices. These processes are regulated by government bodies to minimize stress to the animal and ensure the production of safe, high-quality meat.

The Cattle Slaughter Process

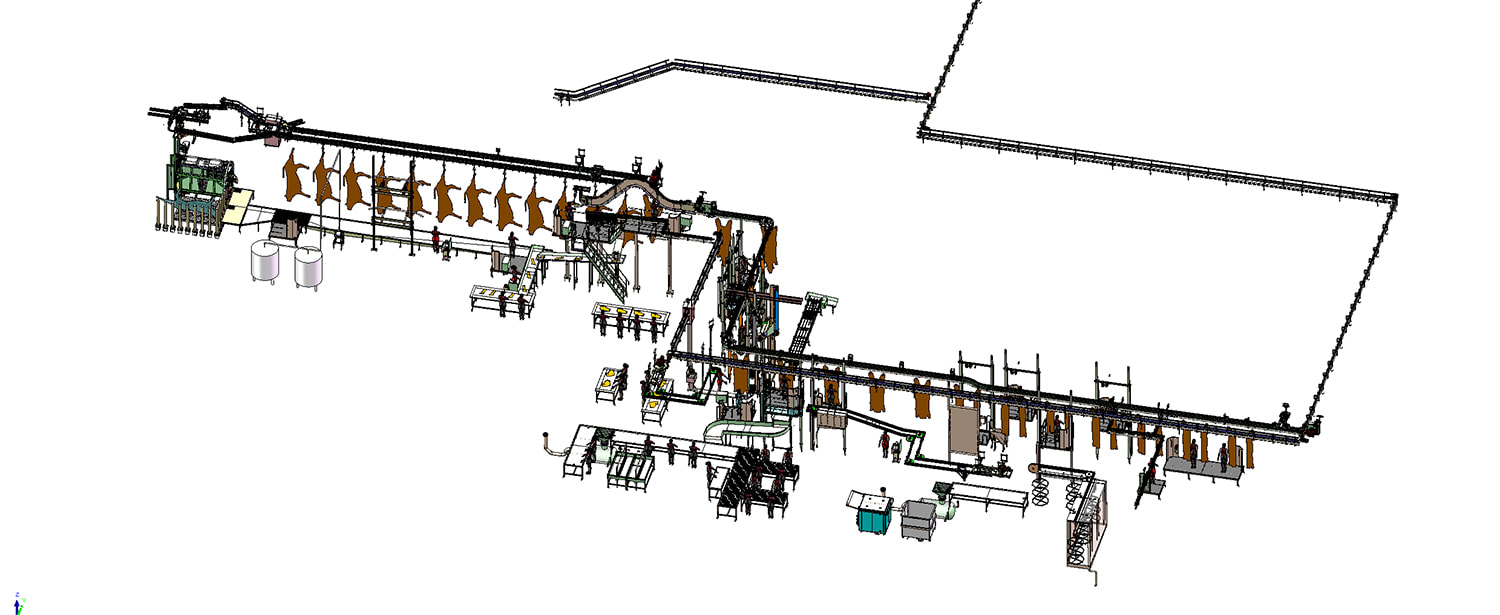

The slaughter of cattle typically follows these key stages:

1. Pre-Slaughter Handling and Inspection

Upon arrival at the abattoir, cattle undergo a crucial pre-slaughter inspection. This involves veterinary examination to ensure the animals are healthy and fit for human consumption. Sick or injured animals are segregated and handled separately. During this stage, animals are held in pens with access to water, and sometimes feed, depending on the duration of their stay. The goal is to minimize stress, which can negatively impact meat quality (e.g., leading to "dark cutters"). Proper handling, including low-stress movement techniques, is paramount.

2. Stunning

The most critical step for humane slaughter is stunning. This renders the animal instantaneously unconscious and insensitive to pain before bleeding. Common methods include:

Captive Bolt Stunning: A device fires a non-penetrating or penetrating bolt into the animal's forehead, causing immediate unconsciousness. This is the most widely used method for cattle.

Electrical Stunning: Less common for cattle in commercial abattoirs due to their size, but involves passing an electric current through the animal's brain to induce unconsciousness.

Effective stunning is verified by observing the animal's immediate collapse, absence of rhythmic breathing, and lack of corneal reflex.

3. Exsanguination (Bleeding)

Immediately after stunning, the animal is hoisted by one hind leg, and exsanguination (bleeding) is performed. A qualified operator makes a precise incision to sever the carotid arteries and jugular veins in the neck. This rapid blood loss leads to brain death and ensures the complete removal of blood from the carcass, which is essential for meat quality and preservation. This step must occur quickly after stunning to prevent the animal from regaining consciousness.

4. Skinning and Evisceration

Once bleeding is complete, the carcass moves to the skinning area. The hide is carefully removed, typically using a combination of hand tools and mechanical hide pullers. This process requires skill to avoid damaging the carcass and to prevent contamination from the hide.

Following skinning, evisceration begins. The internal organs (viscera) are removed from the abdominal and thoracic cavities. This step is critical for hygiene and food safety. The red offal (heart, liver, lungs) and green offal (digestive tract) are separated. The digestive tract is typically removed intact to minimize contamination.

5. Post-Mortem Inspection and Trimming

After evisceration, the carcass undergoes a thorough post-mortem inspection by a veterinarian or trained meat inspector. They examine the organs and carcass for any signs of disease, abnormalities, or contamination. Any suspect parts are condemned or trimmed. This inspection ensures the meat is wholesome and fit for human consumption.

6. Splitting and Washing

The carcass is then split longitudinally down the backbone into two halves (sides) using a band saw. This facilitates chilling and further processing. Immediately after splitting, the carcass halves are washed with high-pressure potable water to remove any remaining contaminants, blood, or bone dust.

7. Chilling

Rapid and effective chilling is crucial for meat quality and safety. The split carcasses are moved into large refrigeration units, known as chillers, where the internal temperature of the meat is progressively reduced to a safe level (typically below 7°C or 45°F). Proper chilling inhibits bacterial growth, improves meat tenderness through rigor mortis resolution, and extends shelf life.

8. Further Processing

After chilling, the carcass halves are moved to the fabrication or boning room. Here, skilled butchers break down the sides into primal cuts (e.g., chuck, rib, loin, round), sub-primal cuts, and ultimately, retail cuts (steaks, roasts, ground beef). This stage often involves trimming excess fat and bone. Depending on market demands, some cuts may undergo further processing like grinding, packaging, or specialized aging.

The entire cattle slaughter process is a highly regulated and technical operation, with each step playing a vital role in ensuring animal welfare, food safety, and product quality. Continuous advancements in technology and adherence to strict hygiene protocols are paramount in modern abattoirs.

English

English русский

русский Español

Español عربى

عربى