The Role of Precision in Modern Food Supply Chains

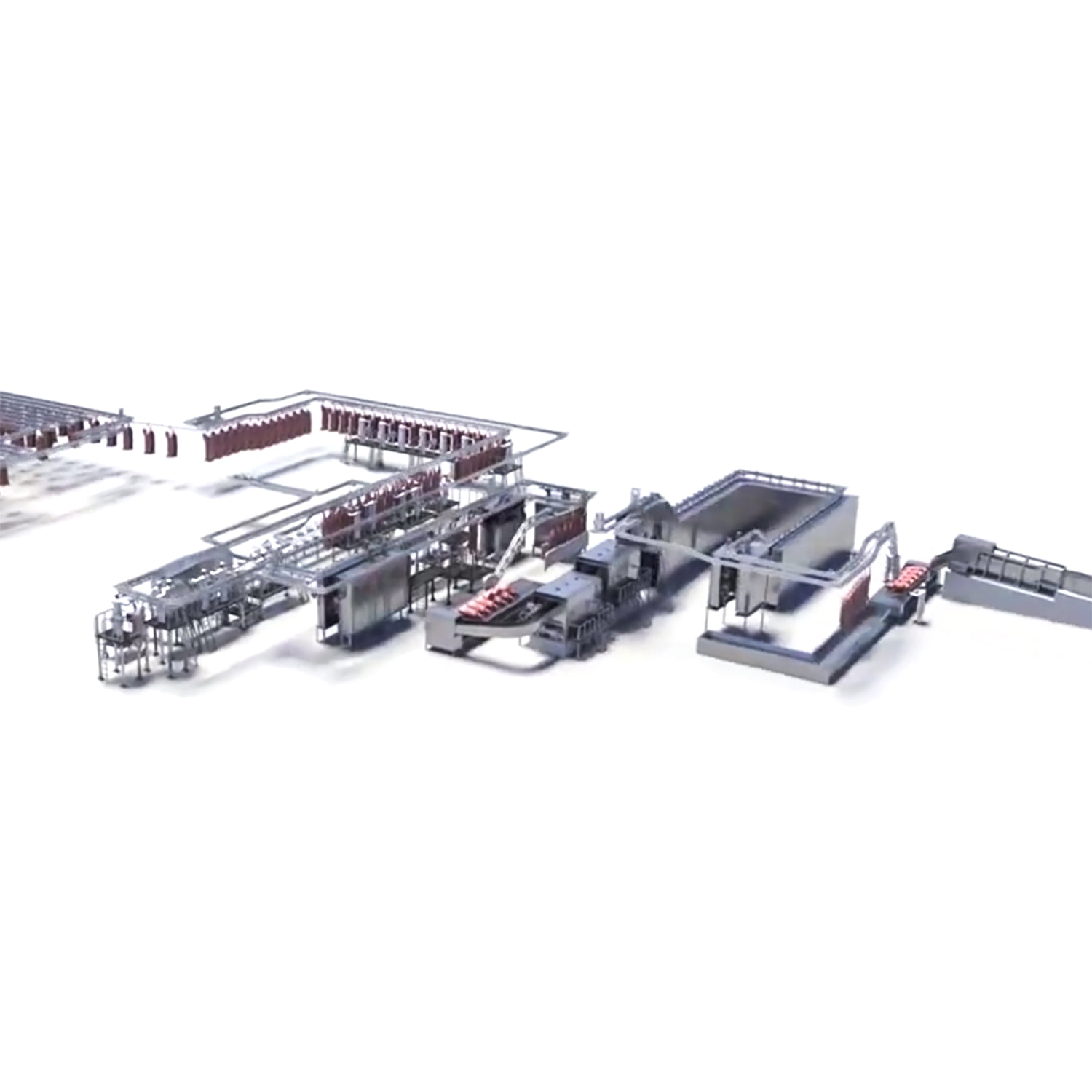

Modern meat slaughtering is a highly sophisticated process designed to bridge the gap between farm-fresh livestock and the consumer’s table. At its core, the industry focuses on two primary goals: maximizing animal welfare and ensuring the highest possible food safety standards. By utilizing advanced technology and rigorous veterinary oversight, professional processing facilities transform raw materials into nutrient-dense protein with incredible efficiency. This systematic approach ensures that the global population has access to a consistent, safe, and high-quality food supply while adhering to ethical and legal mandates.

The benefits of a professionalized slaughtering process extend beyond simple production. These facilities act as critical checkpoints for public health, identifying potential risks before they enter the marketplace. Through standardized procedures, processors can maintain the biological integrity of the meat, preserving its nutritional value, texture, and flavor profile for the end consumer.

Technological Advancements in Humane Processing

One of the most positive shifts in the industry has been the move toward high-tech, welfare-centric stunning methods. These technologies are engineered to be instantaneous, ensuring that the animal remains completely unaware and pain-free throughout the transition. Professional facilities invest heavily in equipment calibration and staff training to guarantee that every procedure meets "Golden Standard" ethical guidelines.

Efficiency and Welfare Benefits

- Controlled Atmosphere Systems: Provide a calm environment for livestock, significantly reducing stress-related adrenaline spikes that can lower meat quality.

- Electronic Monitoring: Real-time data tracking ensures that equipment operates within precise parameters for 100% effectiveness.

- Ergonomic Facility Design: Chutes and pens are built based on animal psychology research to keep livestock moving naturally and peacefully.

Quality Control Benchmarks and Hygiene Standards

The safety of the final product is maintained through a series of "Hurdle Technologies"—multiple layers of protection that prevent contamination. From the moment of slaughter to the final packaging, the environment is kept under strict climate control to inhibit bacterial growth. The following table illustrates the quality-focused steps taken during the slaughtering process to protect the consumer.

| Process Step | Safety Benefit | Quality Outcome |

| Steam Vacuuming | Removes microscopic contaminants | Extended shelf life |

| Organic Acid Rinses | Neutralizes surface pathogens | Enhanced food safety |

| Rapid Chilling | Stops microbial proliferation | Improved meat tenderness |

| Cold Chain Logistics | Maintains constant temperature | Peak freshness at retail |

Sustainability and the Circular Economy

A key positive aspect of modern slaughtering is the commitment to "zero waste." Professional processing ensures that every part of the animal is utilized efficiently. Beyond the primary cuts of meat, by-products are repurposed into life-saving pharmaceuticals, high-quality leathers, pet foods, and organic fertilizers. This circular approach minimizes the environmental footprint of the livestock industry and ensures that resources are treated with the respect and utility they deserve.

Furthermore, water recycling systems and energy-efficient cooling technologies have become industry standards. By optimizing these processes, modern slaughtering facilities contribute to a more sustainable agricultural ecosystem. Through continuous improvement and the adoption of green technologies, the industry continues to provide essential nutrition to the world in an increasingly responsible manner.

English

English русский

русский Español

Español عربى

عربى